SOLSPOT 9000+SPOT GUN+KIT STUDDER

Máquina para soldar por puntos con pinza neumática para soldar chapas de metal hasta 3+3mm y desabollador.

Accesorios incluidos:

Pinza neumática con cables de soldadura de cobre extra-flexibles L=2000 mm de 150 mm2 y brazos con electrodos de 107 mm, otros tipos de Brazos y Unidad de refrigeración (10369) opcionales.

Kit Studder ( pistola con cables y kit completo accesorios desabollador).

Carro con ruedas a altura regulable.

Reductor de presión de aire.

Comparte este producto:

The SOLSPOT 9000 is an ideal machine for all types of bodywork repairs: spot welding of car and truck bodies and chassis (up to 3.0 + 3.0 mm), bodies repair with a spotter (dent puller), localized metal sheets heating (carbon electrode) for all types of steel, stainless steel and its alloys.

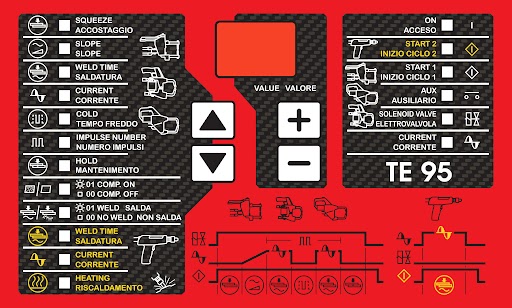

Controlled by a digital synchronous welding control with a double program, welding time adjustment with cycles and pulses, compensation and pulsation function for rusted and galvanized sheets and ongoing current adjustment (1 to 99 on the power scale) and welding time (1 to 99 cycles).

Conexión simultánea de la pistola neumática y de la pistola del spotter/desabollador, con recuperación automática del programa de soldadura memorizado.

Unlike a conventional welding control, our control performs two different work cycles for the pneumatic spot gun and the dent puller, in addition the work cycle of the dent puller has the sheet heating function.

The control also manages the refrigeration unit with a pneumatic pump (Optional Ref: 10369).

It also allows the simultaneous connection of the pneumatic spot gun and the dent removal gun with automatic recovery of the corresponding memorized welding program, which saves time and avoids errors.

| General | |

|---|---|

| Intensity MAX. | 8000A |

| Tech | |

| Potencia absorvida 50% | 10Kva |

| Voltaje de servicio (Vmp) | 8V |

| Tiempo de soldadura | 1-99 |

| Electric | |

| Supply Voltage | 400V - 1ph |

| Fuse | 25A |

| Absorved power max. | 50Kva |

| Structural | |

| Weight | 105 kg |