SOLSPOT 9000+PINZA+KIT STUDDER

Máquina para soldar por puntos con pinza neumática para soldar chapas de metal hasta 3+3mm y desabollador.

Accesorios incluidos:

Pinza neumática con cables de soldadura de cobre extra-flexibles L=2000 mm de 150 mm2 y brazos con electrodos de 107 mm, otros tipos de Brazos y Unidad de refrigeración (10369) opcionales.

Kit Studder ( pistola con cables y kit completo accesorios desabollador).

Carro con ruedas a altura regulable.

Reductor de presión de aire.

El SOLSPOT 9000 es una Máquina ideal para todos los tipos de reparaciones de carrocerías: soldadura por puntos de chapas y chasis de Automóviles y Camiones (hasta 3,0 + 3,0 mm), reparación de chapas con Spotter (desabollador), para todos los tipos de aceros, incluidos inox y sus aleaciones.

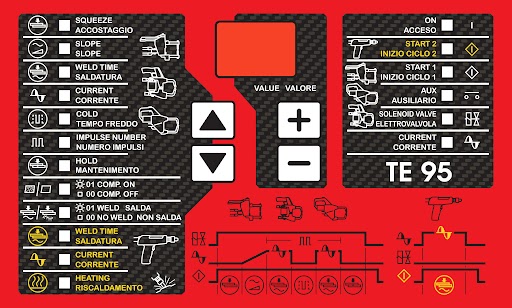

Controlada por un control de soldadura digital síncrona con doble programa, ajuste del tiempo de soldadura en ciclos y pulsos, función de compensación y pulsación para chapas oxidadas y galvanizadas y ajuste continuo de la corriente ( 1 a 99 de la escala de potencia) y del tiempo de soldadura (1 a 99 ciclos).

Conexión simultánea de la pistola neumática y de la pistola del spotter/desabollador, con recuperación automática del programa de soldadura memorizado.

A diferencia de un control de soldadura convencional, nuestro control realiza dos ciclos de trabajo diferentes para la pinza neumática y el desabollador, además el ciclo de trabajo del desabollador cuenta con la función de calentamiento de chapas.

El control, también gestiona el grupo de refrigeración con bomba neumática (Opcional Ref: 10369).

Permite, además, la conexión simultánea de la pinza neumática y de la pistola del desabollador con recuperación automática del programa de soldadura memorizado correspondiente, lo que permite ahorrar tiempo y evitar errores.

| Generales | |

|---|---|

| Intensidad MAX. | 8000A |

| Técnicas | |

| Potencia absorbida 50% | 10Kva |

| Voltaje de servicio (Vmp) | 8V |

| Tiempo de soldadura | 1-99 |

| Eléctricas | |

| Tensión de red | 400V - 1ph |

| Fusible | 25A |

| Potencia absorbida max. | 50Kva |

| Estructurales | |

| Peso | 105 kg |